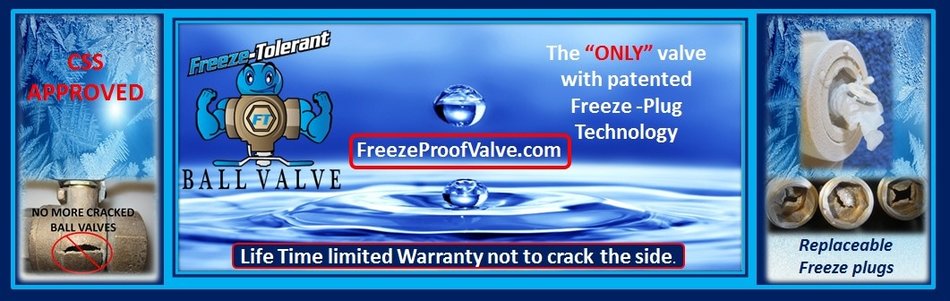

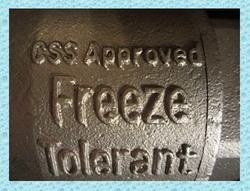

All the Freeze Tolerant ball valves manufactured by Freeze Tolerant Ball Valve Co. are"CSS Approved"- Cold Service Specified. No other valve has this Certification.

Currently there are no official organizations such as the International Association of Plumbing and Mechanical Officials,(IAPMO), that test or certify any plumbing components made to be freeze tolerant. Therefore, until there is such an organization, the manufacturer, has taken steps to set some minimal standards in place so that consumers can be assured that these valves have passed a certain set of standards as outlined below.

1. The freeze plugs have been tested by a 3rd party, such as IAPMO, to see what pressures the plugs burst at under hydraulic pressure.

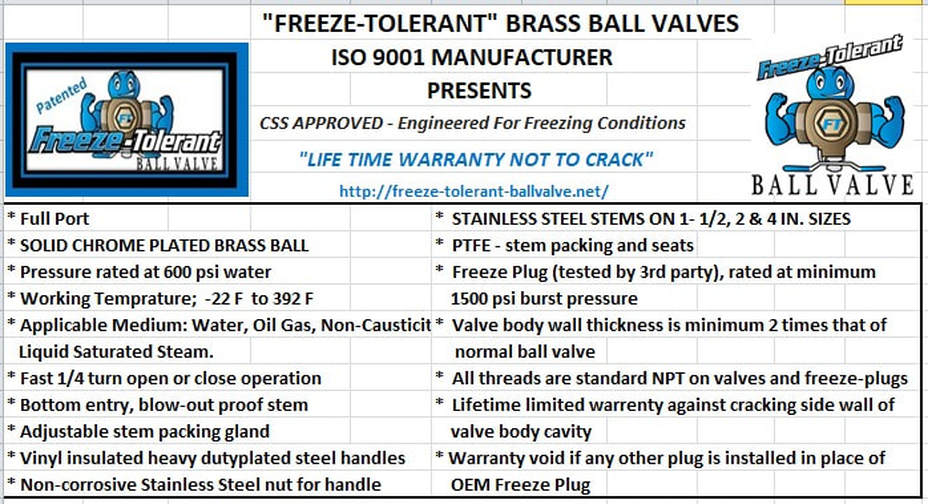

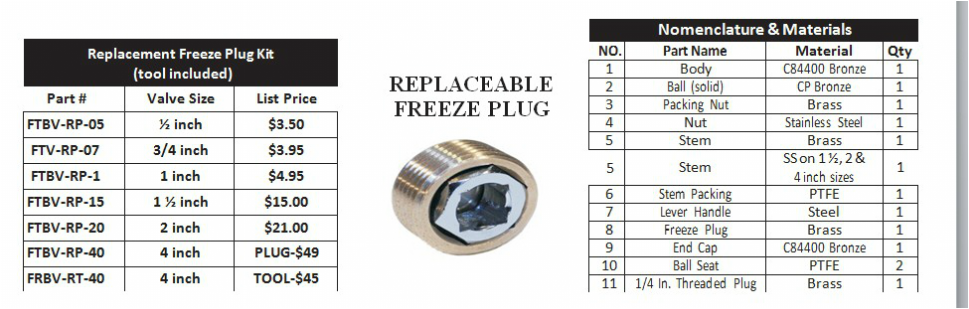

2. The freeze plugs have been designed and machined to withstand certain minimal pressures to ensure that they will not rupture prematurely under normal system pressures. All valves 3/4 inch to 4 inch have freeze plugs that will withstand 1500psi.

3. All freeze tolerant valves have solid balls in them- NOT HOLLOW.

4.The wall thickness of the freeze tolerant valves have at least twice the standard thickness of a regular non freeze tolerant/resistant ball valve.

5. All freeze tolerant ball valves have been freeze tested multiple times with the valves in the closed position, full of water, to ensure the freeze plugs rupture as designed with out any deformation to other areas of the valve body.

GENERAL INFORMATION: We have performed over 300 tests over the last 4 years to determine what happens when brass ball valves freeze with water being trapped within, both in the open and closed positions. Tests have purposefully destroyed both normal and freeze tolerant valves with unbreakable freeze plugs to see where the ball valve will ultimately fail being subjected to over 10,000psi, and then reinforces that area of failure to further build a better freeze tolerant ball valve to last for many years of freezing conditions.

Currently there are no official organizations such as the International Association of Plumbing and Mechanical Officials,(IAPMO), that test or certify any plumbing components made to be freeze tolerant. Therefore, until there is such an organization, the manufacturer, has taken steps to set some minimal standards in place so that consumers can be assured that these valves have passed a certain set of standards as outlined below.

1. The freeze plugs have been tested by a 3rd party, such as IAPMO, to see what pressures the plugs burst at under hydraulic pressure.

2. The freeze plugs have been designed and machined to withstand certain minimal pressures to ensure that they will not rupture prematurely under normal system pressures. All valves 3/4 inch to 4 inch have freeze plugs that will withstand 1500psi.

3. All freeze tolerant valves have solid balls in them- NOT HOLLOW.

4.The wall thickness of the freeze tolerant valves have at least twice the standard thickness of a regular non freeze tolerant/resistant ball valve.

5. All freeze tolerant ball valves have been freeze tested multiple times with the valves in the closed position, full of water, to ensure the freeze plugs rupture as designed with out any deformation to other areas of the valve body.

GENERAL INFORMATION: We have performed over 300 tests over the last 4 years to determine what happens when brass ball valves freeze with water being trapped within, both in the open and closed positions. Tests have purposefully destroyed both normal and freeze tolerant valves with unbreakable freeze plugs to see where the ball valve will ultimately fail being subjected to over 10,000psi, and then reinforces that area of failure to further build a better freeze tolerant ball valve to last for many years of freezing conditions.