All freeze plugs are designed to rupture at 1500 psi or above, so there is no chance of premature rupture during any pressure spikes or water hammer, yet they will rupture before and damage is done to the valve body which usually occurs at above 5,000 psi when ice is forming.

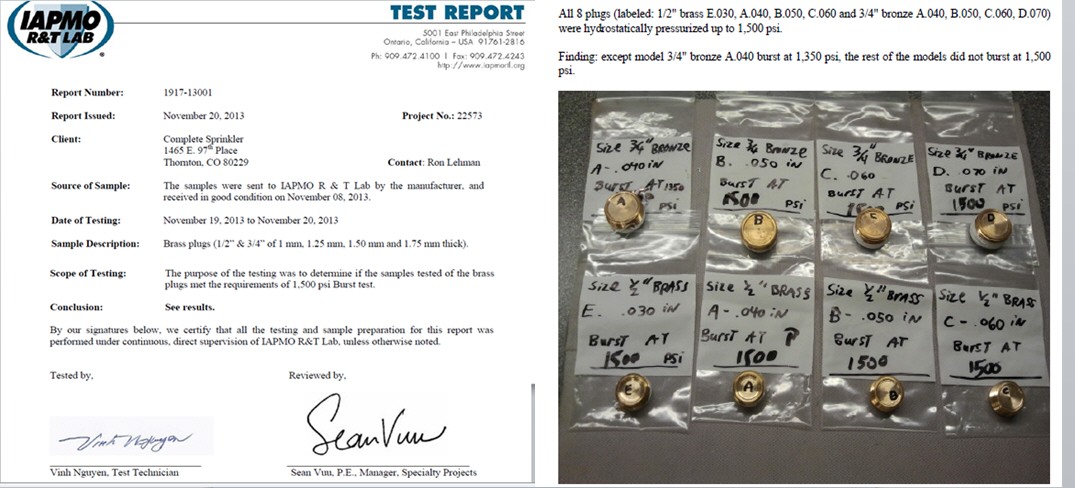

8 sample freeze plugs were sent out for independent testing to IAMPO research & testing lab in California, test report # 1917-13001. 4 different thicknesses in each size were tested to 1500 psi. Only one ruptured, sample A at 1350 psi. Currently all plugs installed have been certified to have withstood 1500psi. Being that the average pressure in a residential irrigation system is around 80 psi, these plugs are safe from premature ruptures and will perform to the highest level of standard and expectation.

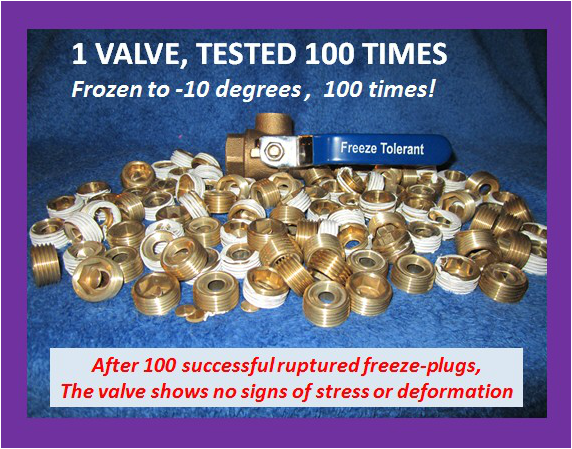

With our in house testing at Complete Sprinkler Services LLC, we are capable of machining a freeze plug to exact tolerances so that we can have total control of how a freeze plug will perform. The burst pressures and rupture areas are 99% predictable and controllable. The freeze plug is designed much like how late model cars are designed to absorb an impact from a collision. There are specific critical areas that are designed to fail (absorb the impact of ice expanding), in a predictable safe pattern to protect the main valve body from damage.

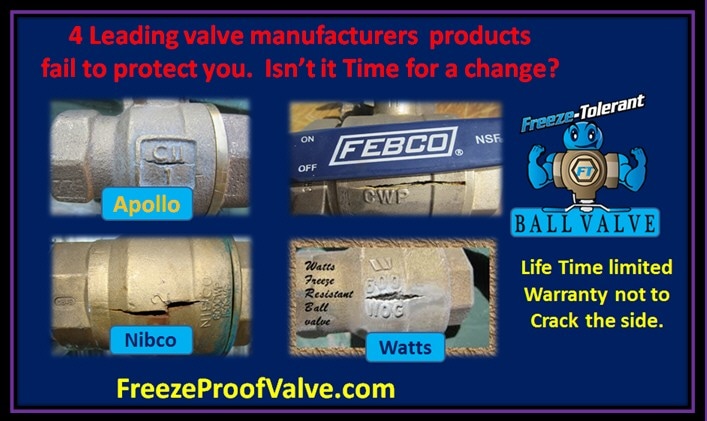

This is the only ball valve manufactured that has incorporated a freeze plug in the body to absorb the damaging forces of expanding ice. This valve was engineered to be frozen. It has a robust design to be reliable freeze after freeze, after freeze.The down side is, most contractors hate it! They know they will never make any $ on replacing it, like the Original Exploding Models ( O.E.M)...